At the start of the interview, Zhao Liming, an electric welder and senior technician at Shanghai Boiler Works, Ltd., seemed somewhat reserved and spoke with a raspy Shaoxing accent. When the topic turned to welding, however, he was in high spirits and spoke with great gusto. Shanghai Boiler Works has produced some of the most advanced boilers in the world, including the tower type boilers of the Waigaoqiao Power Station, and boilers for Taizhou Power Station that require the least amount of coal in the world. Zhao's thirty years of hard work and dedication have made him a prominent figure in electric welding in Shanghai; he has been showered with accolades and commendations from the industry and society. Unmoved by the attention lavished on him, "Master Zhao," as his colleagues call him, remains steadfast.

Starting with the basics, welding requires a combination of perception and an ability to withstand hardship

When asked why he first joined Shanghai Boiler Works, Zhao said, "I came to carry on my father's work."

At the tender age of twenty-five, he set foot onto Shanghai in 1987, and was assigned electric welding work by the Company. Little did he know that he would still be at it after thirty years. Recalling his early days at the plant, Zhao reveals that it was not all smooth sailing. Despite performing relatively well in the orientation training, and earning the recognition of his managers with his hardworking attitude, he faced a setback during his first move up the career ladder. "My managers wanted me to take my welding to the next level, so I had to sit for a skills qualification test on the welding of small alloys. There were a total of seven candidates and one would be eliminated—I was right at the bottom," recounted Zhao with a chuckle. Nonetheless, opportunities come to those who are prepared. Zhao's good performance and hardworking attitude kept him in the race in spite of his less than stellar test results.

Having undergone a month of training, he had thoroughly refined his all-position and horizontal welding skills. Well aware that he still had a long way to go, Zhao resolved to himself, "If we have to weld two parts, I'll weld three; if we have to weld five, I'll weld seven. I must put in twice the amount of effort." Though he got off to a rough start, he went on to pass the test for two assessment items that posed difficulties even for the six other candidates who had participated in the training. As it was highly challenging to pass both items, at least one of the other candidates had failed both of them. Back in the workshop, Zhao had the opportunity to try welding products. He knew this would be his time to shine.

"X-ray images of welds, much like those of the human body, are required to determine if the product passes the requirements." He did more than a hundred welds that day, and the passing score for the assessment was 92 percent. "97 percent of my welds passed muster," said Zhao. He believes that welding is about two factors: perception and an ability to withstand hardship, true to the Company's core values of "Refining Character, Creating Products, Pursuing Excellence." "It takes a good person to make good welds." Zhao's definition of a good person is one who has a quality awareness with an eye for detail. Now leading a team of his own, he requires that all welds pass muster. According to him, as long as standards are set high, nothing is impossible.

Rising above the situation

Zhao describes making welds on small-diameter pipes as "doing embroidery on a pipe." What an epiphany this is, the vivid image of a welder carefully working on a pipe with his tool. During the interview, this reporter noticed that Zhao's hands were covered with bruises and scars from burns. "The sparks produced in the course of welding can burn our arms. Because a seam will be created between the old and new welds if we pause, we grit our teeth and get the job done first."

When he started welding small-diameter pipes, he realized the huge disconnect between what he had learned and what his work required; in practice, endless challenges awaited him at all times. Relative to welds in the plant, 97 percent or more of welds in the horizontal and vertical position can pass muster. However, due to the increased difficulty of welding in certain special positions, getting it right the first time is an insurmountable task. For example, it is much harder to control the surface weld pool for a pipe at a 45-degree angle than it is in the horizontal or vertical position. If typical universal welding techniques are used, the repair rates of welders would be very high. In view of this, Zhao took into account the situation his coworkers were facing and conducted trial and error over and over again, finally arriving at a feasible and effective method. As opposed to welding from the six o'clock position and upwards to the twelve o'clock position, he proposed welding from the three o'clock position downwards to the nine o'clock position. This would ensure a smooth transition to the pipe and therefore fewer defects. Zhao's method was adopted throughout the Company as an advanced technique, raising the percentage of welds in special 45-degree positions that passed muster from 92 percent to 98 percent, which resulted in a considerable cut in expenditure for the Company.

In March 2009, his Welding Method for Small-Diameter 45-Degree and All-Position Base Butt Welds was awarded a national patent.

Power plants of the 21st century are home to upgraded and next-generation boilers, as well as new materials, technology, processes and equipment. These new additions have increased welding difficulty, not to mention the increasingly complex internal structures of boilers—variations include spiral- and irregularly shaped boilers, or weld seams at the gaps and at the back. Zhao, for one, has never wavered in the face of increasingly harsh challenges and takes things as they come. To ensure product quality, he addressed dozens of technical difficulties over a period of time: Argon Welding of T91 Tube Holders in HRSGs, Control of Excess Weld Metal Height in Small-Diameter Pipe Welding, Control of Welding Cracks in Tube Forging of Water Wall of Ultra-Supercritical Boilers, Strategy for Welding T92 Small-Diameter Tubes, China's first Strategy for IGCC Boiler Welding, Control of Welding Cracks in New T23 Small-Diameter Tubes of Ultra-Supercritical Boilers, the first Strategy for Welding Panels of Secondary Reheating Boilers in the country, etc.

Some of these recommendations addressed technical difficulties that arose during the manufacture of China's first 1,000MW ultra-supercritical tower type boiler, such as the welding cracks created when forging T23 tubes and welding cracks in small-diameter pipes. Zhao led his team in conducting an in-depth analysis and repeated testing to modify the existing processes and welding materials without affecting the quality of weld seams. Finally, he obtained a solution to the welding cracks. Aside from solving welding quality issues for the Company, this achievement also saved hundreds of thousands of yuan of repair costs.

Between 2015 and 2016, twelve company and group executives identified fourteen strategic groundbreaking projects that had to be resolved. As such, Zhao, who had become a chief technician as early as in 2006, had to take on these challenges as a strategist of Shanghai Boiler Works and create inroads.

Nurturing trainees and sharing techniques to raise the passing rate

In 2014, his workshop, with the objective of passing on knowhow and creating opportunities for newcomers, was named the Welding Workshop of National Skills Master Zhao Liming. This workshop was the platform on which he raised skill levels and nurtured trainees for many years. The projects were as much about achieving success as they were about nurturing talent in the process. His efforts in developing talent in his team resulted in an outstanding batch of youth. Song Fang (Winner of the National Boiler Industry Welder Competition), Gu Wei (First Runner-Up in the Shanghai Municipal Welder Competition), Yan Guangliang (Third Runner-Up in the Shanghai Municipal Welding Competition), Liang Shuaihui (Winner of the Li Bin Cup Welder Competition) and other top welding talent won accolades for Shanghai Boiler Works, Ltd.

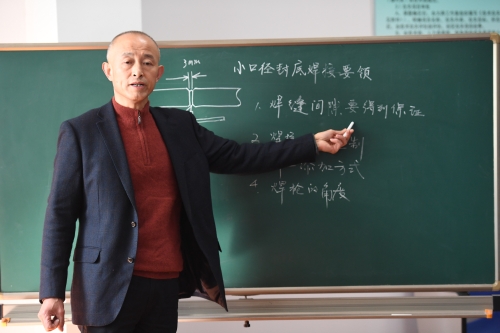

Zhao constantly reviewed new technology in welding, and wrote technical theses. He believed that sharing knowledge would lead to greater development. To continually raise the productivity of the workforce, reduce costs and increase output, Zhao compiled a series of advanced techniques including the following: Preventing Crevices and Incomplete Joint Penetration in Argon and Arc Welding of Butt Joints in Small-Diameter Pipes, Main Points for Welding of Inclined Tubes in Steam/Water Separator of Ultra-Supercritical Boilers, and Butt Welding of Stainless Steel Pipes in Fine Pitches of CFB Boilers. He also led a work group in preparing the Advanced Techniques for Technical Personnel of Shanghai Boiler Works. Six of Zhao's theses were included in this publication and five were given rationalization proposal and achievement awards from Shanghai Electric, the Shanghai Municipality and the National Machinery Industry. Among his theses on advanced techniques, one has been awarded a national patent, and a patent has been declared for another.

Based on the statistics, over thirty theses on advanced welding techniques written by members of his workshop have been included in the seven volumes on advanced techniques for the technical personnel of Shanghai Boiler Works. Every year, Zhao and his team hold seminars on advanced techniques and competitions on technical operations by integrating strategic real-life and technical challenges of the Company's production. These have played a key role in boosting the technical competencies of technical personnel on the ground. Currently, the proportion of welds of Shanghai Boiler Works that pass muster the first time around has stabilized at 97 percent and above. This alone saves the Company millions of yuan or more in costs each year and improves efficiency.

Zhao has played a part in helping the factory improve its performance, and his coworkers have gained experience in the course of such efforts, and the excellent welding techniques developed have also built a good national reputation. Inevitably, this has left him with little time to spend with his children. His generation is one that gives their all in work at the expense of their families, in the interest of the greater good. Zhao also feels strongly about the state's enterprises and is especially particular about welding techniques.

What does craftsmanship mean to him? "Craftsmanship is about dedication, concentration, an eye for detail and patience. When welding, one must have dedication to handle the solitude, full concentration without distractions, an eye for detail to continually improve, and patience to handle adversities calmly," explained Zhao. These are the sincere thoughts of a welder who joined the Company as an ordinary technical personnel and has moved up the ranks to an industry leader.

Zhao's work as a craftsman may not involve as much passion as an artist; however, the spirit of giving his all, day in and day out, through repetition and challenges is priceless. He remains committed to the future of the industry with his sense of responsibility and dedication, and strives to pass on his knowhow, teach and share, in the true spirit of a craftsman.

His simple and yet extraordinary dream is to make China's technology the best in the world.

Profile: Zhao Liming, male, 53, electric welder and senior technician at Shanghai Boiler Works Co., Ltd.

Zhao has received accolades and honors including Model Worker of Shanghai Municipality, May 1 Labor Medal, Mechanical Industry Innovative Technical Expert, Mechanical Industry Skills Master, National Mechanical Industry Chief Gold Worker, Technician With Outstanding Contributions of Shanghai Municipality, and National Technical Expert, as well as a special grant from the State Council.

Personal motto: Be meticulous in your work and do things right the first time.

Accolades: In 2007, Shanghai Electric established The Welding Workshop of Zhao Liming in his name, and in 2014, the Shanghai Human Resources and Social Security Bureau similarly established the Welding Workshop of National Skills Master Zhao Liming. In his career spanning almost thirty years, Zhao has proactively organized activities on strategies for welding, and the review and promotion of advanced techniques by utilizing the workshops as platforms. He has addressed more than twenty welding difficulties for the Company, and received a national invention patent for a revolutionary new outcome (and another national patent declared is pending approval). Eight of his new techniques were given rationalization proposal and technical achievement awards from the Group and the Shanghai Municipality. He is recognized as a Master of Welding and a Knowledgeable Authority within the industry.

Shanghai PNS registry No. 31011502003537

Shanghai PNS registry No. 31011502003537